How To Repair A Hole In A Down Comforter

How to Repair a Leaking Toilet

Updated: February. 28, 2022

How to ready the 4 most common causes of leaks under the toilet.

Fix the 4 about common causes of leaks under the toilet. With the right parts it's easier (and cheaper) than yous think.

You might also like: TBD

- Fourth dimension

- Complexity

- Cost

- A full twenty-four hour period

- Beginner

- Less than $20

three signs of a toilet leaking at the flange

Do you find a minor pool of water where your toilet meets the floor? Does the flooring effectually the toilet feel spongy? Is the finished flooring coming up? If so, you probably have a bad seal between the toilet horn (where the waste exits) and the drain line. Don't procrastinate any longer. Small leaks trapped beneath the toilet volition somewhen rot floor surfaces, and even the underlying framing. Expect likewise long and repair costs ascension, especially when you lot figure in replacing finished flooring and sometimes underlayments, subfloors or even the framing.

In this article, we'll prove you some tips for pulling the toilet (Photos 1 – 3) and then how to diagnose and fix the common causes of leaks. Finally, we'll testify you how to reset the toilet. Afterward pulling the toilet and examining the show, yous may get lucky and just have to replace the wax ring and remount the toilet. If that'south the case, you'll take the stool back on-line in under an hour. You'll find the products nosotros advise for making repairs at whatsoever abode center or well-stocked hardware shop.

Before You Pull the Toilet, Pick Up:

- A new wax ring

- Two sets of 5/16-in. diameter water cupboard bolts

- A tube of silicone-based caulk, in a color to friction match the toilet

- A parcel of plastic toilet shims if your toilet was rocking

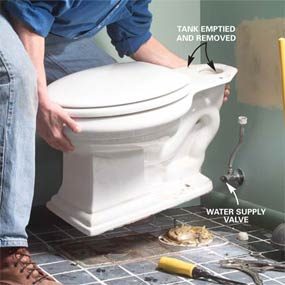

Pulling the toilet

Pulling a toilet is ordinarily simple, but ii issues often crop up. First, one-time water supply valves may not shut off entirely, and 2nd, getting old, corroded water closet nuts loose can be a struggle.

Before pulling the stool, you lot'll have to shut off the water supply valve and remove the water line leading to the tank (Photograph 2). After turning off the valve and flushing the toilet, look in the tank and listen for trickling water. If the water is all the same running, you'll have to shut off the principal water valve in the house and replace the valve with a new 1. Sponge out the excess h2o from the tank and stool.

Then it's time to loosen the water closet basics. If the water closet nuts and bolts are corroded or the bolt spins along with the nuts, information technology'south easiest to just cut them off with a hacksaw (Photograph 1).

OK, the toilet'south off—what do I await for?

You may take ane or more issues to solve, which may require more than 1 fix. So before you lot make up one's mind on a plan of action, check for:

- A broken flange, usually on the outside of the slot that holds the toilet flange bolt (Photos 3 – 6).

- A flange that'due south likewise depression. That includes any flange that'southward more than than 1/four in. beneath the finished flooring (Photos 7 and 8).

- Rot around the toilet flange (Photos 9 and 10).

- Unproblematic wax ring failure. If cipher appears to exist wrong, resetting the toilet with a new wax ring might exist the only affair you need to practise (Photos 11 – fourteen).

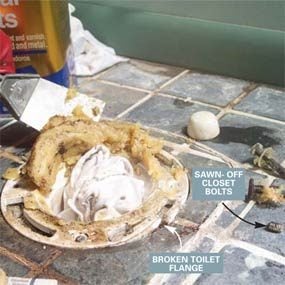

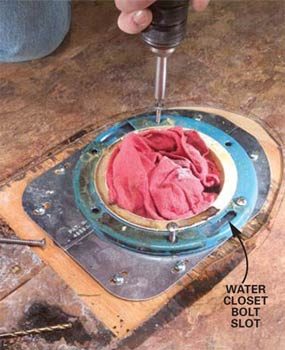

Broken toilet flanges: How to replace toilet flange

Old cast fe and all-plastic toilet flanges are the near probable to break. The problem is usually caused by rocking toilets or overtightened toilet flange basics. Look for a cracked or cleaved rim on the outside of the slots that hold in the bolts (Photos three and four). If y'all accept a broken flange, pick up a reinforcement band along with six 1-1/2 in. No. viii oval-head stainless steel screws. If the flange is on concrete, use one-ane/4 in. long flathead concrete screws (and the recommended masonry drill scrap) for drilling the airplane pilot holes. Follow Photos 4–6 for installation techniques.

Flange Reinforcement Rings

Flange reinforcement rings are essentially bandages that fit over the broken flange and spiral to the floor. They provide a new slot that receives the toilet flange bolts so the toilet can be secured. Y'all may find several styles at the store. The "eared" blazon shown to a higher place is best if screws won't hold well in the former flange holes. Merely make sure the eared type clears any porcelain castings on your toilet. Look at the underside of the toilet and run into if in that location'south a raised porcelain circle around the toilet horn. If it has i, store for the non-eared brass or stainless steel mode shown on the correct.

Fixing flanges that are too depression

Frequently a new bathroom floor is laid on acme of the former one, leaving the toilet flange also low to seal with an ordinary wax ring. The new floor tin be upward of one in. above the existing flange. Doubling up the wax ring isn't a good solution because excess wax can squeeze into the pipe and restrict menses. The taller stack of soft wax likewise has a higher probability of failure. If your toilet flange is more than i/4 in. beneath the finished floor, add plastic toilet flange extenders. Extend the flange until it falls between 1/four in. below the finished flooring and 1/4 in. above it.

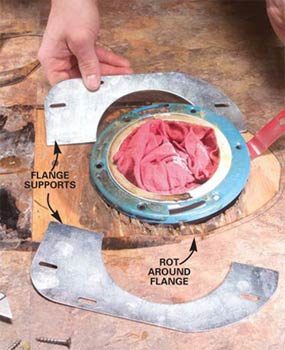

Minimal rot around the flange

A toilet flange that's been leaking can crusade the floor to rot, the flange to loosen and the leak to go worse. You'll take to runway down the cause of the leak, set up information technology and and then provide a solid surface that supports the flange.

The easiest way to stiffen the floor and reanchor the flange is to purchase a flange back up bracket to transfer the load by the rotted areas of the subfloor. The kit comes with all the necessary screws for securing the bracket to the floor and the flange to the bracket. Keep in listen that it will work simply if well-nigh of the support bracket rests on solid flooring. If a toilet has been leaking for years, the rot may be also severe for this gear up. In that example, you'll have to cut out the flooring, replace the subfloor and possibly framing and and so replace the finished flooring. To decide the extent of the damage, probe the floor around the flange with a screwdriver to find where solid wood begins. If the back up rests on solid woods, get ahead with the repair. If the woods is soft more than a couple of inches out from the flange, it needs replacing.

Reset and fix a rocking toilet

Frequently a toilet leaks simply considering the wax ring has lost its seal. By far the most common reason for a broken seal is a toilet that rocks when you sit on it. A toilet that rocks fifty-fifty slightly will eventually compromise the wax ring. If you notice no bear witness of other bug after yous pull the toilet, simply replacing the wax ring and resetting the toilet should set up the trouble. Usually toilets stone because of an uneven floor. Later you set the toilet, shim gaps between the toilet and the floor before caulking effectually the toilet (Photograph thirteen). That'll prevent the toilet from rocking and ruining another seal afterwards.

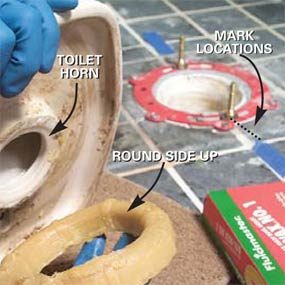

Earlier y'all mount the toilet, push and jerk the wax ring to assist it stick to the porcelain around the horn. That'll keep information technology from falling off as you lower the bowl. When you reset the toilet, information technology'southward important to drop it directly into identify. If it's not aligned straight over the bolts when the wax ring meets the toilet flange, you lot adventure distorting the wax band and ruining the seal. Marking commodities locations with masking tape will help y'all see their position (Photograph 12) as you lower the bowl.

Required Tools for this Project

Take the necessary tools for this DIY project lined upwards before y'all start—you lot'll salvage time and frustration.

ane/4 in. masonry bit

Required Materials for this Project

Avoid terminal-infinitesimal shopping trips by having all your materials ready ahead of time. Here's a list.

Originally Published: November 25, 2022

Source: https://www.familyhandyman.com/project/how-to-repair-a-leaking-toilet/

Posted by: evansdognis.blogspot.com

0 Response to "How To Repair A Hole In A Down Comforter"

Post a Comment