How To Repair Damaged Cabinets

Domicile Repair: How to Ready Kitchen Cabinets

Quick solutions to the almost common chiffonier problems

Introduction

Kitchen cabinets work hard, and all that opening and closing creates a variety of problems. Most are cheap and easy to gear up, and so take a day and plough through them—information technology'll exist like having a new kitchen.

Tools Required

Materials Required

- 1/4-in. plywood

- 1x2

- 3/4-in. plywood

- Back plates for knobs

- Brad nails

- Door bumpers

- Drawer slides

- Dry lubricant

- Magnet catch

- Removable thread adhesive

- Roller catches

- Toothpicks

- Woods cleaner

- Forest fill stick

- Wood glue

For more than on learning how to build your own custom kitchen cabinets without the custom price – check out How to Build Kitchen Cabinets taught by Steve Maxwell!

Project footstep-by-stride (15)

Step ane

Build a Shelf That Won't Sag

Don't bother replacing a sagging shelf with another 1/two-in.-thick shelf or it'll stop upwards sagging too. Instead, cut a new shelf from three/iv-in. plywood. Make information technology the same length and 1-ane/2 in. narrower (so you can add together rails). Then glue and brad smash (or clamp) 1x2 rails along the front and back of the shelf, flush with the ends. The track give the shelf additional support and so it won't sag, even if you load it up with heavy cookware. Apply a polyurethane (or other) finish to match your other shelves.

Step ii

Supervene upon Worn-Out Drawer Slides

Lubricants won't fix damaged drawer slides. They take to exist replaced. This is a mutual trouble on silverware drawers and other drawers that comport a lot of weight. Purchase new slides that are the same, or nearly the same, as your old ones. Then it's just a affair of swapping them out. Y'all'll discover a express selection of drawer slides at dwelling centers, merely there are dozens of online sources. These sites also sell the plastic mounting sockets that adhere to the back of the cabinet to hold the slides in place.

Step three

Adapt Euro Hinges

Adjusting cabinet doors with European hinges is equally easy equally turning a spiral or 2. Hinges like this one accommodate in three directions; others adjust in two. If your door is kleptomaniacal—non foursquare with the cabinet—gear up that first, so raise or lower it to the same height equally adjacent doors.

For crooked doors, adjust the side screw on one hinge, which moves the door from side to side. It'due south a trial-and-error procedure. Make a small adjustment, so close the door to check its position. If the door is college or lower than adjacent doors, loosen the mounting screws on both hinges, raise or lower the door, then tighten the screws. Identify a straightedge beyond the door elevation or bottom to make sure information technology'due south level with neighboring doors.

If the door sticks out too far from the cabinet or the swivel side brushes against the cabinet when you open the door, accommodate the depth screw. Some hinges move the door as yous plough the depth screw; others require y'all to tap the door in or out and then tighten the screw.

Door adjustments aren't as piece of cake if you have traditional hinges. If your doors are sagging, start try tightening the screws. If the hinges are aptitude, replace them if you tin find a match.

Stride 4

Silence Banging Doors with Bumpers

Doors and drawers slam loudly when forest smacks against wood. That's why most have "bumpers" nigh the interior corners to absorber the touch and reduce the noise. Simply the bumpers sometimes fall off (or kids option them off). Get new ones at abode centers. Peel off the backing and stick the bumpers in identify. They're available clear or with felt, and in unlike thicknesses. Use bumpers the same thickness as those on adjacent doors.

Stride five

Fill In Stripped Screw Holes

When the screws in your hinges or drawer slides turn but don't tighten, the spiral hole is stripped. That can forestall doors and drawers from closing properly. Fix the trouble with glue and toothpicks. Beginning by removing the hardware. Then utilise a drop of forest gum to the ends of toothpicks and cram as many as volition fit into the hole (perhaps but two or three). Wipe away any gum that drips out. Let the glue dry, and then use a utility knife to cut the toothpicks flush with the chiffonier or drawer. Reinstall the hardware, driving the screw through the filled hole.

Step 6

Beef Upward Wimpy Drawer Bottoms

The sparse plywood used for drawer bottoms sometimes gets wavy. Stiffen upward the bottoms with 1/4-in. or 3/8-in. plywood. Cutting the plywood to fit over the drawer bottom, leaving about a ane/4-in. gap on each side. Apply forest glue on the drawer lesser and ready the plywood over information technology. Set a gallon or two of paint over the plywood to hold it in place until the glue dries.

Step vii

Glue Loose Knobs

Once knobs autumn off your cabinets, twisting them dorsum on won't solve the problem. They'll just keep coming loose. Apply a dab of thread agglutinative to proceed them in identify (Loctite 242, bluish, is i brand that will hold the knob in place without gluing it permanently; it'due south sold at hardware stores and home centers). Apply the adhesive to the screw, then attach the knob. If you determine to replace the knob later, don't worry. You can remove it with a screwdriver. (If you lot purchase a different brand, look for a removable type.)

Step 8

Renew the shine

Grease splatters and smoke tin can leave a film on your cabinets, dulling the stop. Launder the cabinets with a woods cleaner to bring dorsum the luster. Potato Oil Soap is one type of cleaner.

Use a sponge to rub the cleaner onto the cabinets. Cleaners like Murphy'due south don't need to be rinsed off, which cuts your cleaning time. For stubborn grease spots, scrub lightly with the cleaner using a No. 0000 steel wool pad. Cleaning the cabinets once a year keeps them shiny and protects the finish.

Skip the store and get this miracle cleaner from Amazon right here.

Step 9

Repair Disrepair Drawers

Some drawers are held together past only a few drops of mucilage or short brad nails. When you outset notice a drawer corner coming autonomously, take out the drawer and fix it. And if one corner is failing, others probably will too. Save yourself time to come hassles by repairing all the weak corners now. Identify a slice of scrap forest against a corner and lightly rap it one time with a hammer. If the corner comes apart, fix it. If not, it should agree up.

To set the corner, first remove the drawer front, if possible. Almost fronts are attached by screws driven from within the drawer. Remove any fasteners from the corner, then scrape away the former glue with a utility knife. Reglue the corner, tap the sides dorsum together and clamp the drawer until the gum dries.

Step x

Repair a broken drawer front end

Photo one: Reinstall the drawer front

Remove the drawer pull and screws. Then line upwards the mortise-and-tenons and the drawer lesser with the groove and tap the drawer front end back onto the box.

Photograph 2: Reinforce the drawer front

Drill 4 i/8-in. pilot holes through the newly installed box front. Then bulldoze coarse-thread drywall screws through the new box front and into the old drawer front.

High-quality chiffonier drawers are congenital with a sturdy box and a separate decorative drawer front end. But the drawer fronts on economic system cabinets are role of the box itself. They're attached to the sides and bottom with a mortise-and-tenon articulation and held with glue and staples. Repeated openings and closings pause the joint and the drawer front falls off. You tin can effort regluing the articulation, but information technology won't last. Hither's how to fix the problem permanently.

Cut a 3/4-in.-thick slice of wood to match the width and top of the drawer box. And then remove the staples from the tenons and make clean upward the crude edges then you tin reinstall the drawer forepart (Photo 1). Glue the new woods block directly behind the drawer front (use polyurethane gum if the box sides and bottom take been varnished). Secure with nails or screws. And so attach the former drawer forepart to the new wood cake (Photo 2).

Using the old drawer pull holes as a guide, drill through the new wood block. Buy longer No. eight-32 10 1-three/four-in. car screws and remount the drawer pull.

Step 11

Add Dorsum Plates to Embrace Worn Areas

Years of opening doors and drawers can wear away the finish near cabinet knobs. Instead of undertaking the fourth dimension-consuming task of refinishing the cabinets, try this quick fix: Install back plates under the knobs or handles. Simply unscrew the knob or handle, slide the back plate nether information technology, then reattach the knob or handle. Back plates are inexpensive and are available in a wide range of styles. Yous can special-order them at home centers or buy them online.

Footstep 12

Supercede Bad Latches

Older cabinets sometimes take "roller catches" that hold the doors airtight. If you accept these and your door won't close or stay closed, loosen the screws to slide the catch forrad or backward on the cabinet frame. Or replace it if it's broken. The catches are available at home centers.

Step xiii

Fill in Scratches

Apply a wood fill stick to make scratches less visible. The stick fills in and colors over the scratch. Soften the stick with a hair dryer to make the application easier. And so run the stick over the scratch and wipe abroad any excess with a cloth. The fill up probably won't be an exact match with the surrounding chiffonier, but information technology'll be shut. The sticks piece of work on shallow and deep scratches. They're available at dwelling house centers and hardware stores.

Step 14

Lubricate Sticking Drawers

The gear up for sticking drawers is like shooting fish in a barrel. First remove the drawer. Wipe the drawer slides and the cabinet track with a clean cloth to remove whatsoever debris. So spray a dry lubricant direct on the drawer slides. Cans are sold at home centers; it'll say "dry out lubricant" on the label. Replace the drawer and slide it in and out of the chiffonier several times until it glides easily. If the drawer is still hard to open, replace the drawer slides.

Dry lubricants won't leave an oily rest that attracts dirt and grit. The lubricants also work nifty on squeaky hinges.

Step 15

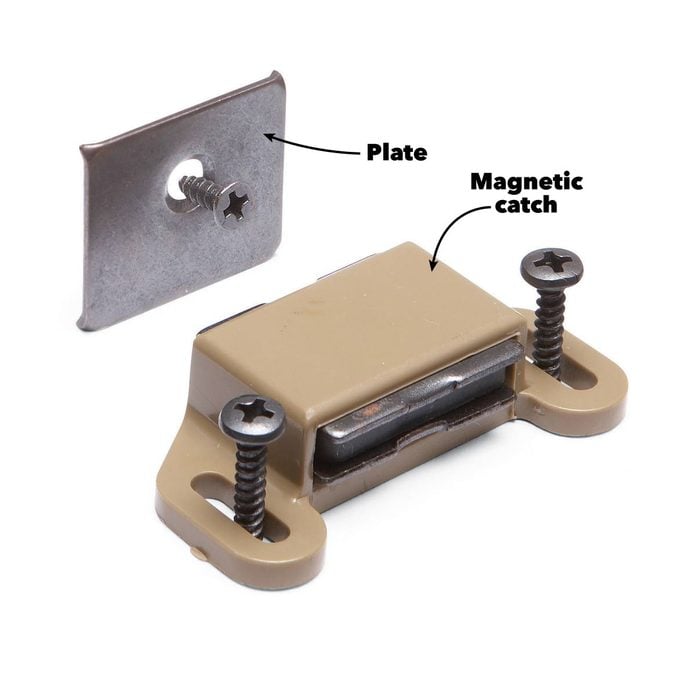

Pull Doors Shut with Magnets

Sure, this trick is as old as Benny Colina jokes, but information technology still works. When your cabinet door is warped and won't fully shut, simply install a magnetic grab (sold at home centers) at the problem area. Screw the magnetic catch to the chiffonier rail or stile and the plate to the door. The magnet pulls the door closed.

Originally Published: June twenty, 2022

Source: https://www.familyhandyman.com/project/home-repair-how-to-fix-kitchen-cabinets/

0 Response to "How To Repair Damaged Cabinets"

Post a Comment